According Bernauli equation, there are three kinds of head (energy) of the fluid flow system installations, namely, pressure energy, kinetic energy and potential energy

It can be expressed by the following formula:

Because energy is eternal, then the shape of the head (high press) can vary at different cross sections. But in fact there is always a loss of energy (losses).

1 Head Pressure

Head pressure is the difference in pressure head acting on the surface of the liquid at the press with head pressure acting on the surface of the liquid at the suction side.

Head pressure can be expressed by the formula:

Head speed is the difference between head velocity of liquid at the channel hit with a head speed of liquid at the suction channel.

Head velocity can be expressed by the formula:

Total static head is the difference in height between the surface of the liquid at the surface of the press with liquid at the suction side.

Total static head can be expressed by the formula:

Z = Zd - Zs (5)

where:

Z: Head static total

Zd: Head of static on the side of the press

Zs: Head of static on the suction side

The +: If the surface of the liquid at the suction side of the pump is lower than the axis (Suction lift).

Signs -: If the surface of the liquid at the suction side is higher than the pump axis (Suction head).

4 Losses head (head loss)

Loss of energy per unit weight of fluid in the drainage of fluid in the piping system referred to as head loss (head loss).

Head loss consists of:

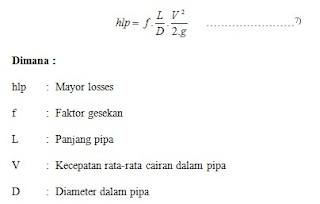

a. Major head loss (major losses)

Is the energy loss along the pipeline expressed by the formula:

While the magnitude of Reynolds Number can be calculated by the formula: b. Minor head loss (minor losses)

Is the head loss in fittings and valves located along the pipeline system. Can be searched by using the formula:

c. total Losses

Total losses are total losses piping systems, namely:

Thanks for sharing blog post about head pump.

ReplyDeletesewage pumps

raw water pumps

Thank you for sharing this informative blog post about pumps! I truly appreciate the insights you've provided.

ReplyDeleteCentrifugal Chemical Pump Manufacturer

A malfunctioning water heater repair can disrupt daily life, leaving you without hot water for essential tasks like bathing, cleaning, or cooking. Common issues include insufficient heating, water leaks, or unusual noises. Timely water heater repair not only restores functionality but also prevents further damage and costly replacements. Professional technicians can diagnose and fix problems efficiently, whether it’s a faulty thermostat, sediment buildup, or a damaged heating element.

ReplyDelete